Your Source for Rausch Equipment and Maintenance Services

Carter’s Equipment & Specialty Products is the sales representative for the Southeast region in the U.S. Contact us today to set up a demo!

Rausch Cameras

Rausch Mainline Pipe Inspection Camera and Crawler

Application range 5.5″ to 60″ pipe diameter

The Rausch pipe inspection CCTV camera system consists of the steerable four-wheel drive L135 Tractor with an electrical lift and the pan and tilt KS135 camera. The rugged system is built to inspect sewer, water, and storm drain pipes from 5.5″ up to 60″ pipe diameter.

The Camera, KS135

- Range: 5.5″ to 60″ pipe diameter

- 280° pan, infinite 360° rotation

- Auto and manual focus

- Auto and manual iris

- 10X optical zoom and 12x digital zoom (120:1)

- Auto homing

- Four (4) long-range, high-power LED lights

- Six (6) short-range, high-power LED lights

- Quick-connect military-style cardanic C-connector, cam-locked to tractor with protected contacts

- Nitrogen-pressurized for moisture protection with sensor-leak detection

- No exposed wires, cables, or contacts

- Additional lighting can be directly mounted on camera head (no exposed wires)

L135 Tractor Platform

- Application range: 5.5″ to 60″ pipe diameter

- Studio-controlled electric lift

- Two powerful motors for steerable 4-wheel drive

- Anti-rollover feature with on/off control

- Variable speed, joystick controlled

- Inclination sensor

- Automated and sensor-controlled synchronization to main cable reel

- Weight: 43 lb; length: 20.5″; diameter: 5.4″

- Material: anodized brass, fully CNC-machined from a solid block

- Extremely quick setup time for various pipe sizes

- Cardanic military-style, heavy-duty connector to main cable

- Mechanical ‘quick-lock’ connector to all cameras and modules; no exposed wires or contacts

- Nitrogen-pressurized for leak protection with sensor-leak detection

- Complete wheel sets for various pipe conditions

- Stackable tires can be placed over currently equipped tires for faster setup

- Optional: integrated locater transmitter (33 kHz or 512 Hz)

- Optional: integrated rear-view camera

- Optional: additional weights (maximum of 40 lb)

L100 Cross Tractor + KS60CL Camera

- Application range: 4″ to 16″ diameter

- Three driven axles for 4″ diameter

- Extremely low center of gravity due to tilted wheel positioning

- Manual and automated steering

- Tilt-able screw-on adapter for the KS60CL camera, no exposed cables

- Mechanical height adjustment

- Direct additional Power-LED light attachment for diameters larger than 6″ – no exposed cables

- Cascading of up to three (3) lighting modules

- Small cardanic connector with integrated pull sensor for synchronization.

- Integrated sonde locater built into KS60CL camera.

Rausch Lateral Launch System

For inspecting lateral taps from the mainline.

- Application range: 6″ to 48″ pipe diameters

- Up to 160 ft. of lateral push distance.

- Up to 550 ft. of mainline cable.

- Automatically synchronized cable reels.

- Electronic distance counter.

- Quick-Connect to the tractor for extremely easy and quick setup. (Plug & Play)

- Connects to electric lift of the L135 tractor.

- ZKM135 auxiliary camera for direct observation of launch.

- High-power LED’s in the PM135 for accurate positioning and camera insertion.

- PM135 can position the lateral camera to launch into angles greater than 90°.

- SKM135 launch module pushes the camera into the lateral and can launch against the flow.

KS60CL Pan and Tilt Lateral Camera

Lateral launch action

- As small as 4″ lateral

- Electrical auto-upright picture

- Infinite 360° rotation

- 300° pan motion

- Detachable steering pin to negotiate branched laterals

- Integrated sonde transmitter (33 KHz or 512 Hz)

- Nitrogen pressurized with sensor-leak detection

- 6 high-power LEDs for superior illumination

- Diameter: 2.44″, length: 5.07″, weight: 1.43 lb

- Connects to up to 160 ft. lateral push cable

MC SAT40 Auto-Upright Lateral Camera

MC SAT40 Mobile

- Application range: 2″-8″

- Self-leveling auto upright picture

- Integrated sonde transmitter (512 Hz)

- High-resolution color camera module with 520 TV-lines

- 0.05 Lux / F1.2

- Lens protected by 3 mm sapphire glass; 136° angle of view

- 10 chip LED light ring

- Outer diameter: 40 mm

- Connects to up to 160 ft. lateral push cable

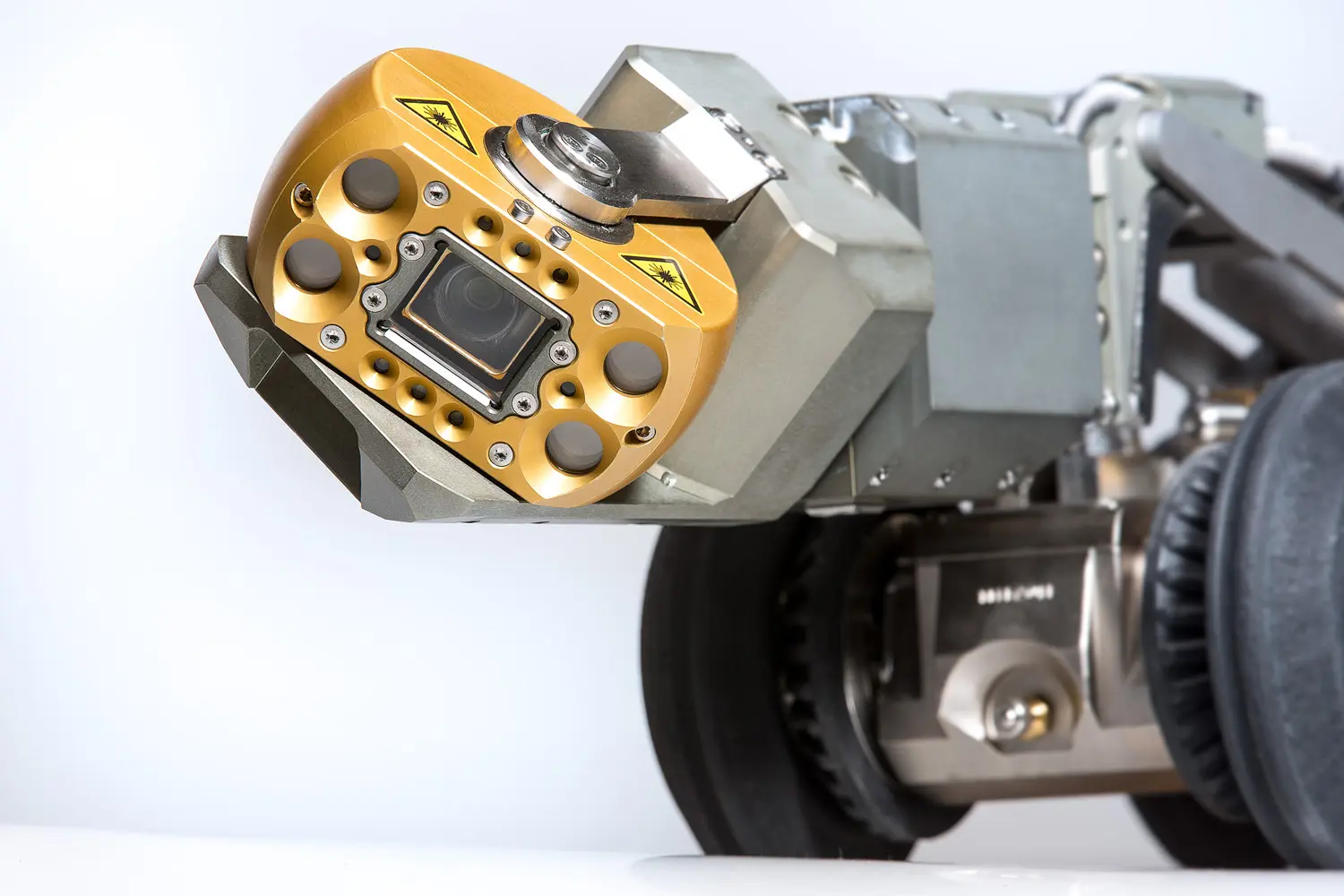

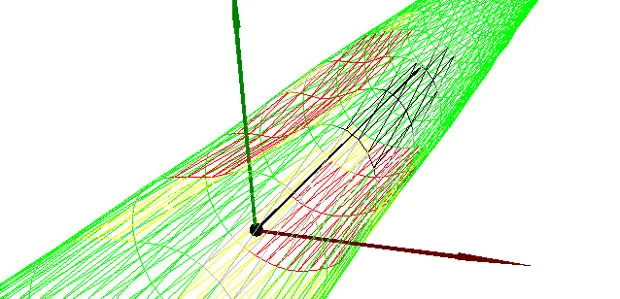

Laser Pipe Profiling

For pre and post-inspection using “spinning laser” profiling technology. It is a 3-in-1 system, and a single-module upgrade to the L135 tractor/crawler platform. Two laser diodes are integrated on either side of the conventional CCTV camera lens to perform three functions:

1. Conventional CCTV video pipe inspection

2. Laser profiling – precise measurement of diameter, deflection, and deformation of pipe

3. Crack and joint measurement

Standard application range from 8″ up to 48″ pipe diameter (up to 72″ diameter requires additional equipment and upgrades)

Advantages of the Rausch Laser Profiler

- Integrated into camera module

- Mounts onto the L135 tractor platform

- Direct and highly accurate measurements

- Instant and final reports on-site with POSM Pro software

- No third-party analysis

- No field calibration necessary

- Instant system verification

- Quick and easy setup

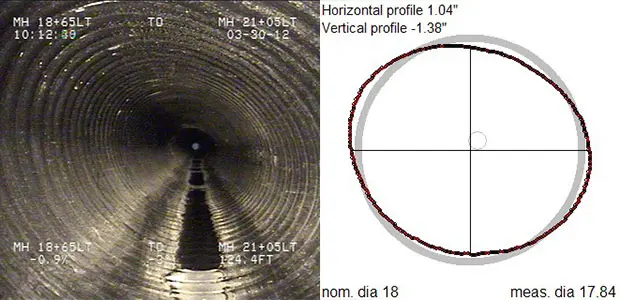

How It Works

The Rausch Laser Profiler features two laser diodes that are integrated into the KS135 Scan camera head. When these laser diodes project laser dots onto the inner pipe wall, the camera head rotates to measure the diameter and all changes thereof via triangulation calculations. This method is called the “spinning laser” laser pipe profiling technology. Working in conjunction with the POSM software, the comprehensive scan generates easy-to-use reports to profile the pipe.

Detailed Operation

On the way into the pipe, the system is used to perform conventional CCTV video inspection, as well as to measure all joint widths. In addition, individual laser measurements can be taken at any time to determine the actual pipe diameter and deflection, called a single-point scan. These diameter and deflection measurements then become a part of the inspection report.

On the way out of the pipe, the system performs a “spinning laser” scan of the entire pipe length. The camera head swivels perpendicular to the pipe wall and rotates at a defined speed. Via triangulation, the scan software continuously calculates the precise pipe diameter and all deflections and deformations in the pipe profile. Once the run is completed, the software instantly generates graphs in 2- and 3-D. These graphs show any deflection, the average pipe diameter, and the inclination slope of the line.

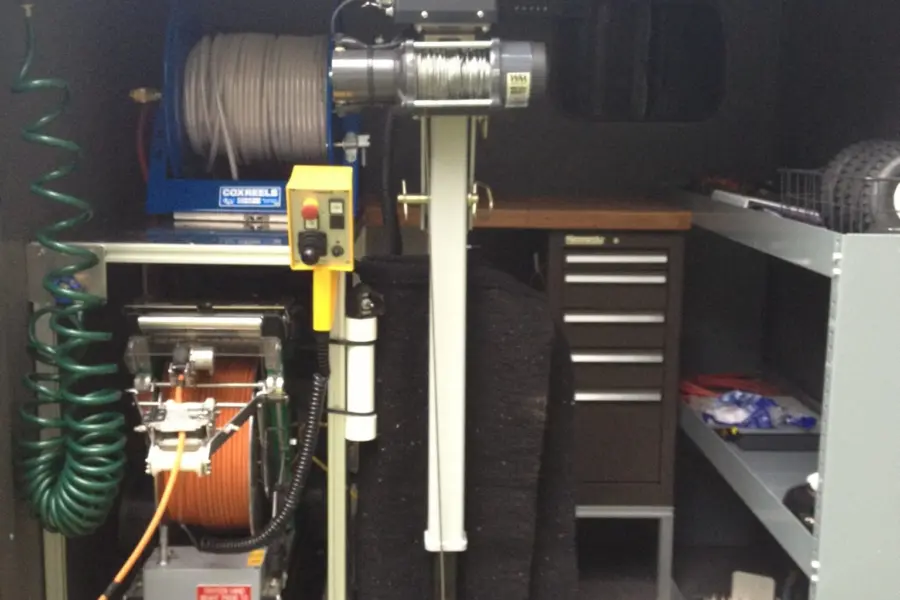

Rausch Vehicle Builds

Check out these photo examples of various Rausch vehicle-mounted systems. All Rausch systems can be installed in any vehicle chassis of your choice and customized with various layouts.

MinCam Push Cameras

The minCam push cameras are reliable and advanced inspection tools for a broad range of applications.

| Advanced | Model | Range | Camera | Cable Type | Push Length | Monitor | Sonde |

|---|---|---|---|---|---|---|---|

| mC30 Duo push camera system | mc30 Duo | 0.6″ – 8″ | KK13 KK29SL | Flexible push-pull 6.7 mm push rod | 30 ft. 100 ft. (up to 160 ft.) | 5.6″ monitor | 512 Hz 512 Hz |

| mC50 Duo push camera system | mc50 Duo | 2″ – 16″ | KK29SL KK55SL | 6.7 mm push rod 9.2 mm push rod | 100 ft. 200 ft. (up to 260 ft.) | 8.4″ monitor | 512 Hz 512 Hz |

| minCam 360 pan and tilt push camera | minCam360 | 3″ – 16″ | Pan & Tilt | 9.2 mm push rod | 200 ft. (up to 300 ft.) | 8.4″ monitor | Tri-Band |

| mC Series | Model | Range | Camera | Cable Type | Push Length | Monitor | Sonde |

|---|---|---|---|---|---|---|---|

| minCord intro | minCord | 0.6″ – 3″ | KK13 | Flexible push-pull | 50 ft. (up to 100 ft.) | 3.5″ monitor | 512 Hz |

| mC15 Set push camera | mc15 | 1.2″ – 5″ | KK18 | 5.6 mm push rod | 100 ft. | 5.6″ monitor | 512 Hz |

| mC30 push camera with 1 inch self leveling camera | mc30 | 2″ – 8″ | KK29SL | 6.7 mm push rod | 100 ft. (up to 160 ft.) | 5.6″ monitor | 512 Hz |

| mc50 with 2 inch self leveling camera | mc50 | 3″ – 16″ | KK55SL | 9.2 mm push rod | 200 ft. (up to 260 ft.) | 8.4″ monitor | 512 Hz |

| mC80 Set push camera | mc80 | 4″ – 16″ | KK55SL | 11.2 mm push rod | 425 ft. | 8.4″ monitor | 512 Hz |

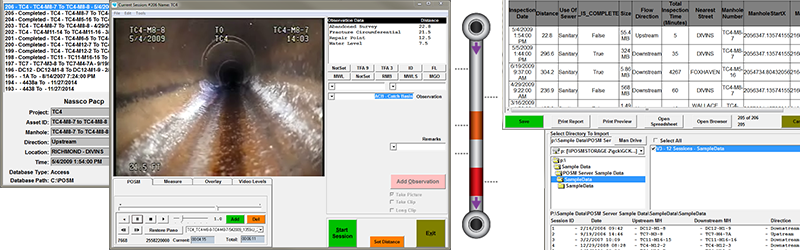

POSM Inspection Software

We have a close working partnership with POSM to use their POSM Pro inspection software in our Rausch CCTV inspection vehicles.